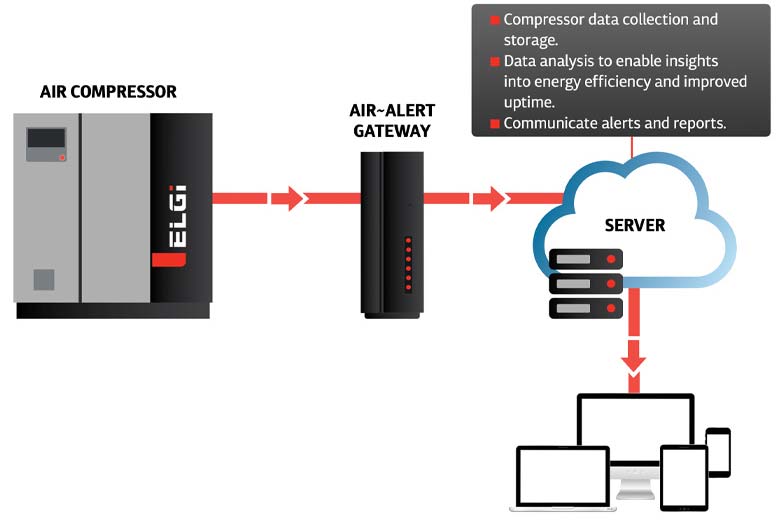

The ELGi Air Alert system initially gathers information from the compressor, setting the foundation for in-depth analysis. The operational and performance data from your compressor is acquired by Air~Alert from the compressor controller, transmitted in an encrypted form, and sent to secure and dedicated Air~Alert cloud servers.

The data collected from the air compressors is structured and then analyzed to provide intelligent insights that help the users to plan their maintenance activities and provide operational data, enabling energy efficiency improvements in the compressed air system.

The ELGi Air Alert system generates and disseminates critical alerts and reports, allowing users to address any issues promptly and efficiently. These alerts and reports are translated into comprehensible formatted data for ease of understanding for the users.

Our engineers analyze the data to extract valuable conclusions and recommendations for equipment health and downtime reduction. Air-Alert eliminates downtime by expediting after-sales services through real-time transmission of compressor performance data. The data collected through Air-Alert aids in product development, providing insights for designing better machines in the future. The system has been successfully tested in various industries, such as a pipe company, which contributed to 40% energy savings, and a textile company, where it detected an abnormal pressure reading, helping identify a choked air filter.